My father in law was diagnosed with Parkinson disease he can still drive his car thanks to his medication. but the disease make him have enormous problems getting the seat belt on himself. So this is a tool that enables him to reach the seat belt better.

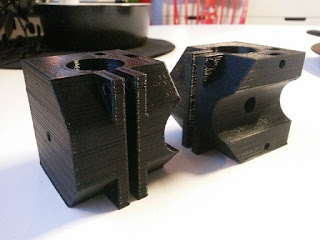

you simply clip it on the seat belt right below the buckle. (see picture)

It's a print in place thing but i used support for some of the over hanging parts (touching buildplate) see my screenshot for the places that needs it.

there is 2 different versions one that's simply snaps on and off and one that is more permanent with a little screw or a pin its up to you.

My printer settings on my reprappro mono mendel is:

Supports: Yes

Resolution: 0.25 mm

Infill: 20%

Speed: is up to you and your printer.

I must say that this sort of project is what makes 3Dprinting so priceless. Someone needs help and there is nothing to by. And when I get this sort of problem solving on my table I'm so happy to be able to help. :-D

And I realized when i was making it and tried it out. It's real good after chest day :-P (I'm a weightlifter)

There is more pictures if you follow the link or click here